Finishing Technology

Precision • Quality • Craftsmanship

Experts in Complex Edging Services

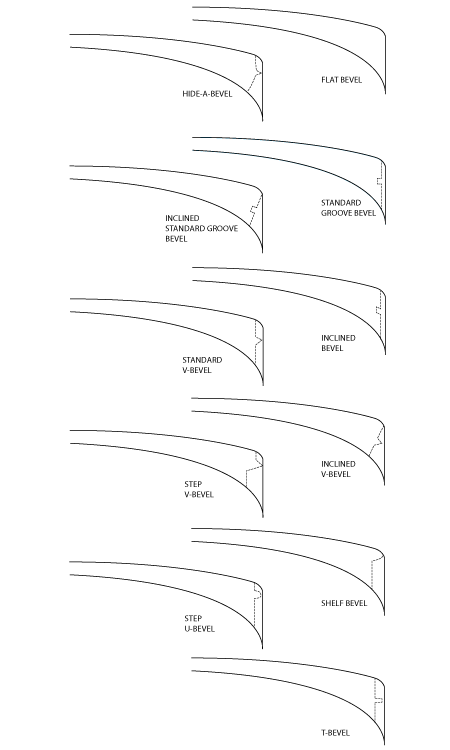

Complex Bevels

Features and Advantages

Custom Laser Engraving

Fancy something unique or different for your lens? Then why not get your initials, a design that you like or even a custom design of your own. Give your lenses a touch of individualization.We work closely with our customers to meet their quality and delivery requirements and we can turn around simple and custom designs in a matter of hours.

iCoat’s Laser Engraving services can handle orders from one to several thousand. We can receive your special marking information on a disk, via e-mail or any other media. Please call us for more information on the media and file types we accept.

Features of Laser Engraving

Because of the precise nature of the laser beam and high positioning accuracy, quality and precision are always consistent.

Any type of logo, trademark, alpha-numeric, icon, symbol, or graphic design can be applied in almost any shape and size.

Assures fast turnaround time and cost effective marking because of pre programmed CNC processing.

All optical lens materials including plastics, poly, trivex, and hi-index materials can be marked.

Almost any plastic type item can be marked, from lenses to frames to cases.

High positioning accuracy of the laser markings repeat from part to part with same accuracy and tolerance.

Allows for all shapes from flat to concave and convex to be marked with no tool wear or significant influence on the part.

The process is self contained and generates no waste products.

*All laser markings should be legal including trademark, logos and images.